A friend called me that other day and asked if I was OK? I'm fine! She said, "Well, you haven't updated your blog in a while, and I wondered if you were still around."

Ooops! I guess it has been a while...

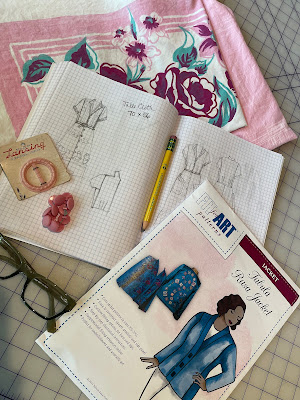

My sewing challenge this year is to make a garment each month starting with the Tabula Rasa Jacket pattern from Fit For Art patterns. It is going very well. I am really enjoying the different things I have made and still have some ideas that I am excited to sew. The tricky part is, that I asked Threads Magazine if they would like to follow along and they did. Great! BUT...they ask that I not post something that will be on their site before they post it. That means, by the time they get the monthly challenge garment posted, I am a month or two ahead of them. By that time I have moved on and forget to go back and post the garments here! ANYWAY....it's all good and I will try to remember to share them here.

My April project was an Easter dress. I can't remember the last time I actually got a new Easter dress. Growing up it was a huge spring ritual. The dress, new shoes, the hat, the gloves and the coat. All very proper. Many of my projects are inspired by a particular fabric and the minty green linen that had been languishing in my stash, called out to be an Easter dress.

Truth be told, it was basically a shirt dress. Pretty darn simple. But the collar that I chose and the ceramic buttons really made the simple lines seem very special.

I spent most of an afternoon drafting a cut on facing that would hold the collar only to realize that there was no way I would have enough fabric to do a facing. Plan B....

I found a really lovely cotton batik that looked just great with my linen. Not only did I get the facings that I needed, I was able to add pockets to the dress as well....yeah for plan B's.

I am really pleased with the final dress...Easter Parade here I come!

...so that was April...My May creation has just been posted on the Threads site so I can share that one as well....

In May I made another dress. This time it was an homage to my birthday. I decided I would make a dress that referenced my birth year. 195? ahem.....OK, yes, I am old! It would have a fitted bodice with a cut-on wing collar and a full 'twirly' skirt. It was a bit of a breech of protocol, because I started with the design before I had the fabric. This usually does not end well.

I figured that cotton broadcloth would be a great choice for the given idea, and that I would have no trouble finding something I liked in one of several quilt shops in my area. Hmmmm...think again!

I just couldn't come up with anything that had the 1950's color vibe that was in my head. Another Plan B...

I ended up finding a lovely tablecloth with just the right color quality and even came up with vintage buttons and a belt buckle to complete the dress! The Tabula Rasa pattern worked really well to make the fitted bodice. I was worried that the large scale print would be hard to match, but it turned out just perfectly...I think!

I have no idea if I will ever have an occasion to wear my birthday dress, but it was so much fun to create.

An homage to the 1950's would not be complete without a hula-hoop...so I will leave you with this...